Fastener Testing

Don’t call them screws, they’re Fasteners! The Fastener Industry produces hardware devices that are used to join or affix two or more objects together. They are usually used to create non-permanent joints so that the joints can be removed or dismantled without damaging the joining components. Fasteners are used in Aerospace, Automotive, Building and Construction, Furniture, Industrial Machinery, Motors and Pumps, and many other industries.

Why is Fastener Testing So Important?

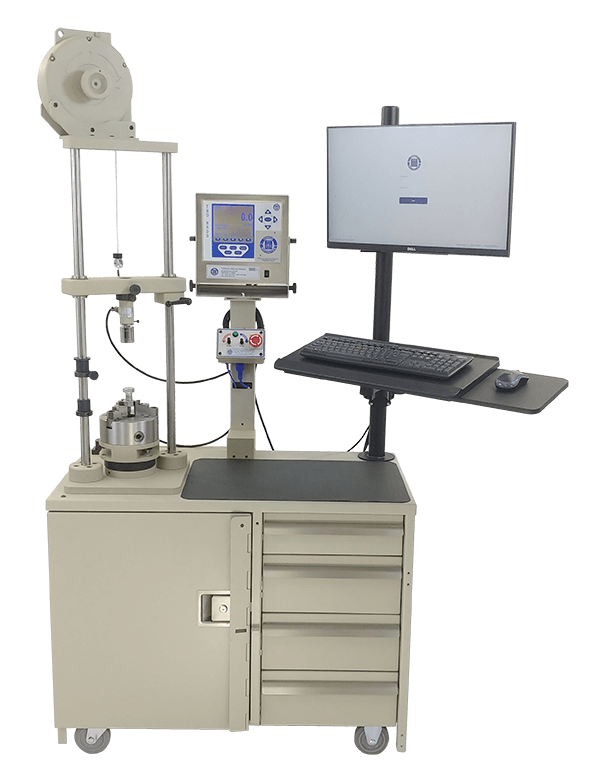

Fastener testing is an essential safeguard, ensuring that seemingly simple components like bolts, screws and nuts meet the precise torque specifications their applications require. In many industries, like aerospace, military, and transportation, fastener performance isn’t a matter of chance – it’s a matter of life and safety. A.K.O.’s fastener testing equipment can be used manually or configured with a motor to automatically test the integrity of the fastener.

Contact Us About Our Fastener Testing Systems

AKO manufactures full rotation, automated fastener torque testing machines that are used to cycle-test fasteners to ensure torque specifications are compliant with industry tolerance requirements. Many large fastener manufacturing companies use AKO’s Fastener Torque Testing Systems to test fastener production quality and ensure that each production lot will perform to its designed specifications when used in the field.

If our standard product offerings don’t fit your unique requirements, contact us for more information about custom solutions.