Highly Repeatable Fastener Testing Systems

A.K.O.’s Fastener Testing Systems are engineered to help manufacturers ensure that critical fasteners meet application-specific requirements. From aerospace to pharmaceuticals, our systems deliver accurate, repeatable results using manual or automated torque-based methods. With a broad range and customizable setups, our fastener testing equipment supports quality assurance and compliance across demanding industries.

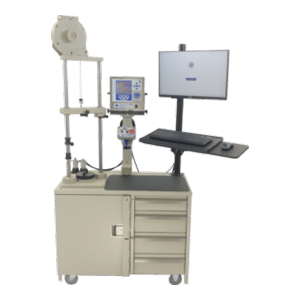

Automated Fastener Testing Systems

A.K.O., Inc. Automated Fastener Testing Systems facilitate the repetitive testing of fasteners in an automated fashion. Each system uses a motor and gearbox to perform full rotation tests, simulating real-world applications. When paired with A.K.O.’s Torque Transducers and TSD6500 Digital Indicator, these systems deliver industry-leading accuracy and repeatability.

Designed with minimal space and power requirements, our fastener testing equipment is ideal for both production and lab environments. Built with durable components and long-life in mind, they integrate easily into existing operations.

The PRO series represents the latest generation of A.K.O., Inc.’s line of torque-based fastener testing systems, featuring:

- A newly engineered drivetrain system

- TorqCal Pro software for programmable test patterns and result validation

- Enhanced user interface and automation capabilities

- Automated pass/fail verification

- Certificate generation based on collected data

These systems streamline quality control and documentation, helping manufacturers meet tightening compliance standards with ease.

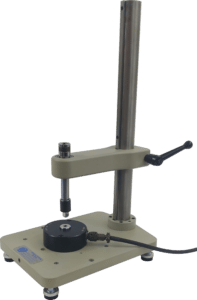

Manual Test Stand

TSD1220

The TSD1220 is a manual system designed to measure the breaking value of shear nuts, or determine the precise torque at which a fastener will shear. Used in conjunction with a Torque Transducer and a TSD6500 Indicator, this setup provides accurate, repeatable results.

The TSD1220 is a manual system designed to measure the breaking value of shear nuts, or determine the precise torque at which a fastener will shear. Used in conjunction with a Torque Transducer and a TSD6500 Indicator, this setup provides accurate, repeatable results.

To conduct a test, the fastener is placed in the Torque Transducer using a socket. The technician then applies torque manually using a ratchet or breaker bar until the nut or fastener shears. The Peak Hold function of the TSD6500 captures and displays the maximum torque value for easy recording.

Ideal for quality control and small-batch testing, the TSD1220 supports multiple Transducers to accommodate a large range of torque applications up to 300 lbf. ft.

Industry Applications for Fastener Testing Systems

Fastener integrity is critical in many high-performance and safety-sensitive industries. A,K.O.’s fastener testing systems and equipment are trusted by manufacturers and suppliers across a wide range of sectors, helping ensure compliance, quality control, and product reliability. Industries we serve include:

- Aerospace: Validate torque and tensile requirements for aircraft components and structural fasteners.

- Commercial Aviation: Maintain torque and fastener integrity in flight-critical systems and cabin components.

- Defense: Test fasteners used in military vehicles, weapons systems, and high-security assemblies.

- Oil & Gas: Provide fastener durability in high-pressure and corrosive environments such as pipelines and offshore platforms.

- Power Generation: Evaluate fasteners in turbines, generators, and transmission equipment where high torque and load-bearing capacity are essential.

- Calibration Laboratories: Use our fastener testing equipment to verify and certify fastener torque accuracy across a range of torque values and test configurations.

Our fastener testing equipment is designed to support a wide range of industries beyond those listed here. Contact us to find the right solution for your needs.

Features of Our Fastener Testing Equipment

- Rugged Base Cabinet and Servo Drive

- Lockable Storage and Accessory Drawer

- Powerful Servo Drive System

- 24” Touch Monitor

- TSD6500 Digital Indicator with support for up to 8 transducers

- Wide range of available 0.1% Torque Transducers

- User Friendly TorqCal PRO Fastener Software

- Programmable Test Parameters and Cycles

- Precision position and RPM speed control

- Digitally Controlled Jog Feature

- 110/220 VAC 50/60 Hz Power Requirements

- Power Consumption: 10 Amps Max

- System Accuracy = 0.1% of reading

- Capable of torque outputs up to 300 lbf-ft

- Special Drive Adapters and Mandrels

- Custom Solutions for specialty applications

Contact Us About Our Fastener Testing Equipment & Systems

If you have questions about A.K.O.’s fastener testing systems or torque calibration services, please contact the AKO sales team in Windsor, CT to discuss your specific application.